Plastic Injection Manufacturer with Customized Service For Many Industries - Mulan Group ![]() Contact@china-plasticparts.com +86 021 3479 1660

Contact@china-plasticparts.com +86 021 3479 1660

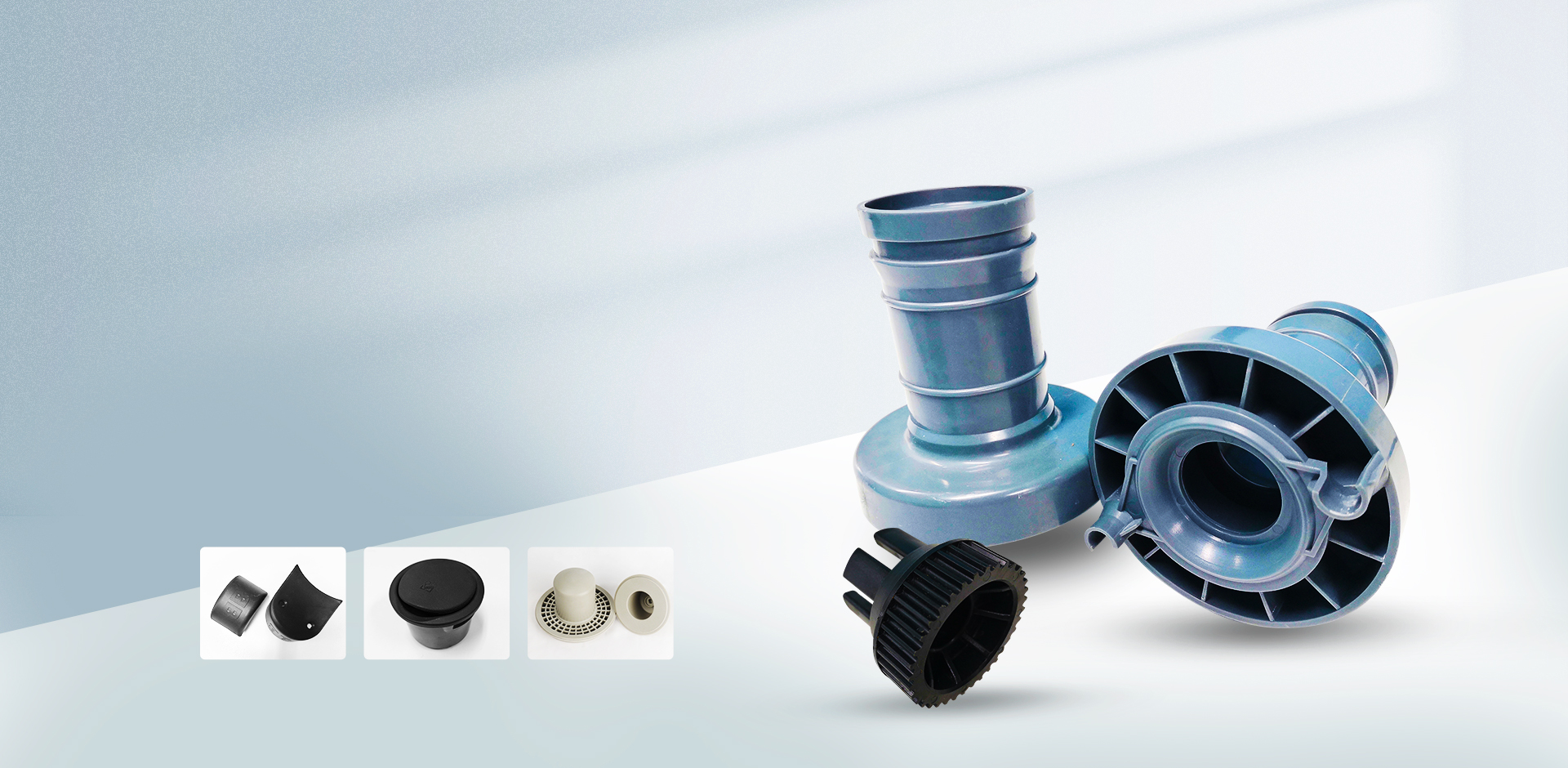

FULL RANGE Plastic Injection Molding MANUFACTURING

As one of the plastic injection moulding suppliers in China, Mulan Manufacturing Group provides high-quality plastic moulding parts for customers worldwide.

Our plastic injection moulding services includes: plastic injection molding, thermoforming, rotational molding, blow molding and compression molding, etc. An experienced team of engineers and an efficient sales team provide quick feedback to all custom plastic parts production project queries for global buyers. We currently owns 2 manufacturing companies and holds 3 processing plants. Welcome Visit!

PLASTIC OVERMOLDING SERVICE

Free mold & injection molding technical support

Free mold & injection molding technical support On-demand DFM feedback

On-demand DFM feedback No minimum order quantity limit

No minimum order quantity limit Rich professional knowledge and experience

Rich professional knowledge and experience On time delivery

On time delivery Real Chinese manufacturer's cost quotation

Real Chinese manufacturer's cost quotationPlastic Injection CASEs

As a professional plastic injection factory, Mulan Manufacturing Group focuses on custom plastic parts over 18 years.

Our main services include injection molding, thermoforming, rotational molding, blow molding and compression molding. If you are looking for a reliable, quick-turn plastic mold maker of machined plastic components, no further than Mulan Group. With hundreds of advanced equipments, our unmatched in-house capacity ensures your parts are shipped on-time, every single time. At Mulan Group, our AS9100-certified facilities are designed for both rapid prototyping and low-volume production of end-use components.

INQUIRY ME NOW, GOT THE PRICE LIST.

We are committed to producing the best quality custom plastic molding products at the most competitive prices. Therefore, we sincerely invite all interested companies to contact us for more information. Our objective is "good quality for survival, good faith for development, using new technology to improve product quality"

ABOUT MULAN GROUP

Mulan Manufacturing Group specializes in the manufacturing of plastic moulding parts. We are the leading custom plastic injection molding manufacturer in China. And we have been engaged in the customized production of plastic parts for more than 18 years. Mulan Group uses advanced processing equipment and scientific quality management system to provide global suppliers with one-stop customized plastic parts production solutions. Mulan Group provides a cost-effective one-stop supply service with an efficient sales team, reasonable low-cost quotation and strong manufacturing resources.

Rich production experience allows Mulan Group’s services to meet the products of various industries. Mulan Group has participated in many important product development and manufacturing to understand the use characteristics and requirements of different products. In other words, only a brief description of the customer, the production plan and the actual cost of the product can form a formal report.

One-Stop Production.

One-Stop Production. 500+ company personnel, professional R&D team.

500+ company personnel, professional R&D team. Pro Manufacturing Team.

Pro Manufacturing Team.Major Industries Served

NEWS

Mulan Manufacturing Group has participated in many important product development and manufacturing to understand the use characteristics and requirements of different products. In other words, only a brief description of the customer, the production plan and the actual cost of the product can form a formal report.

Contact Us Today For a Free Quotation

contact one of our in-house experts today for advice on the system best suited to your needs

Contact us, provide you excellent custom service

QUICK LINKS

mulan Cases & Services

CONTACT US