Plastic Molding Company with Customization Service For Many Industries - Mulan Group ![]() Contact@china-plasticparts.com +86 021 3479 1660

Contact@china-plasticparts.com +86 021 3479 1660

Applications of Plastic Molding in Packaging Industry

How to Choose the Suitable Plastic Molding Service For Your Product Packaging

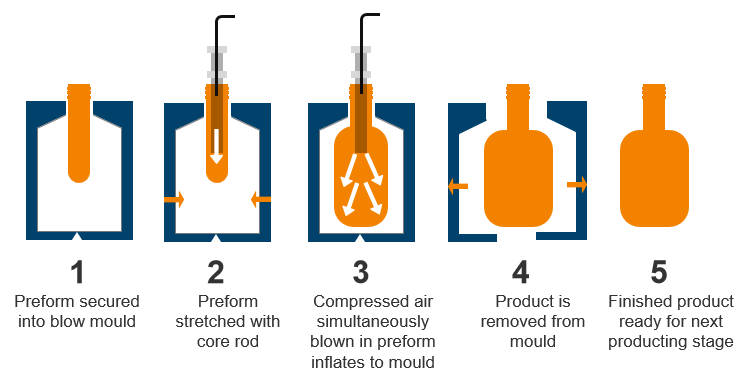

Therefore, based on the above process comparison, we can clearly know that food packaging gives priority to food-grade materials (such as PP, PET) and process cleanliness; industrial packaging focuses on mechanical properties and weather resistance. In addition, it is necessary to balance mold investment and unit cost. For large quantities, injection molding/blow molding is selected, and for customization, rotational molding/molding is selected. Simultaneously optimize the wall thickness design to reduce material waste and improve molding efficiency.

Of course, you can also choose to cooperate with Mulan Group for plastic molding of packaging containers, which can help you save a lot of time and energy, because Mulan Group, as a professional plastic molding factory, has 18 years of experience in custom plastic molding, and can give the most appropriate suggestions and custom plastic parts according to customer needs.

LEAVE A MESSAGE

Our team is dedicated to making sure all parts you order are delivered on time and meet your quality expectations.

QUICK LINKS

mulan Cases & Services

CONTACT US