شركة صب البلاستيك مع خدمة تخصيص للعديد من الصناعات - مجموعة مولان ![]()

Contact@china-plasticparts.com

+86 021 3479 1660

Contact@china-plasticparts.com

+86 021 3479 1660

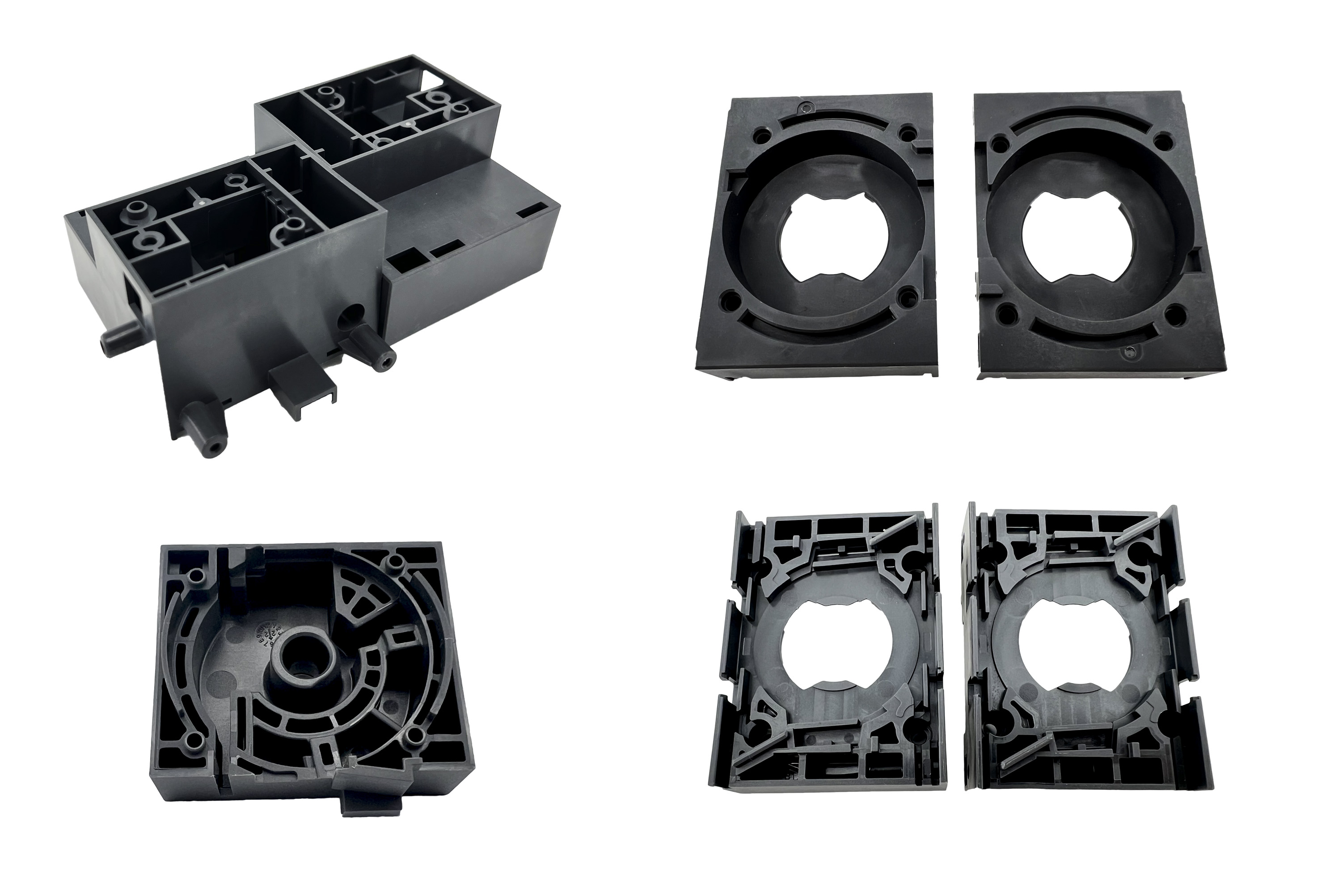

Best Multi-insert Nylon Glass Fiber Products Company - MULAN

Multi-insert nylon glass fiber products compared with similar products on the market, it has incomparable outstanding advantages in terms of performance, quality, appearance, etc., and enjoys a good reputation in the market.

MULAN summarizes the defects of past products, and continuously improves them. The specifications of Multi-insert nylon glass fiber products can be customized according to your needs.

Nylon glass fiber products, its strength, hardness, fatigue resistance, dimensional stability, degeneration resistance, etc. have been greatly improved, but also greatly reduce the water absorption and shrinkage of raw materials, with excellent dimensional stability and excellent mechanical strength

Widely used in automobiles, electrical appliances, railways, machinery and other fields, Jingcheng industrial control nylon glass fiber products cover machine tools, household appliances, 5G stations, new energy vehicles, photovoltaic control, medical testing and other industry products

Multi-insert nylon glass fiber products are also the unique advantages of Jingcheng Industrial Control, with more than ten years of production experience and production experience of different inserts and a variety of products, and stable quality.

Nylon glass fiber products, its strength, hardness, fatigue resistance, dimensional stability, degeneration resistance, etc. have been greatly improved, but also greatly reduce the water absorption and shrinkage of raw materials, with excellent dimensional stability and excellent mechanical strength Widely used in automobiles, electrical appliances, railways, machinery and other fields, Jingcheng industrial control nylon glass fiber products cover machine tools, household appliances, 5G stations, new energy vehicles, photovoltaic control, Medical testing and other industry products.

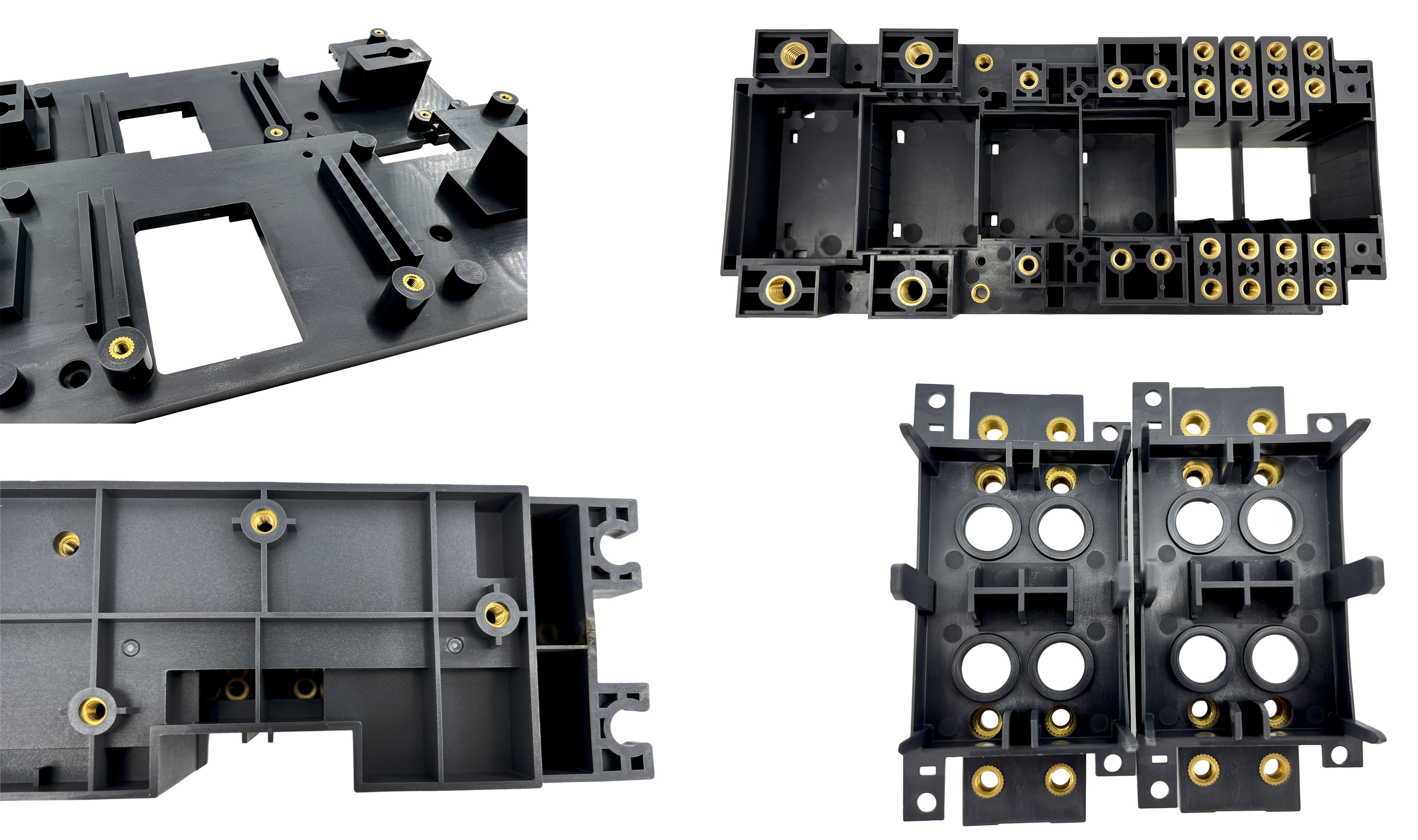

In the actual production process, the size of glass fiber reinforced nylon injection molded products changes during water absorption; Brittleness caused by incomplete water absorption; It is easy to have poor surface appearance, mainly glass fiber exposed, burnt, flower, dent, silver grain, ripple, overflower, etc. Jingcheng Industrial Control adopts Japanese Matsui centralized feeding system, and the whole process of drying and feeding is carried out in a closed environment; Reduce moisture absorption problems caused by contact with air during feeding; Cross-contamination of fine particles of different raw materials on site. Solve the problem of molding processing, the residual moisture in the raw material causes vaporization into water vapor, and crosslinks or degradation with other volatile low molecular weight compounds; It is manifested in the inside or surface of the part, forming silver wires, markings, bubbles, pockmarks, impurity markings (dots), brittle cracks and other defects.

Mold temperature is the most basic parameter in the injection molding process and is particularly important for glass fiber reinforced modified nylon. Sincerely committed to combining mold temperature control from mold cooling (heating) system design to production process; According to the structural characteristics of the product, determine the temperature difference between fixed mold and moving mold, mold core and mold wall, mold wall and insert; Effectively solve the exposed glass fiber, glass fiber silver grain, joint seam, corrugation (material streamline), overflow, warping deformation, molding of slender thin-walled parts. Make the surface of the part smooth and shiny, and improve the surface and beauty of the part It also improves the strength and appearance of the fusion line.

The reasonable opening of the exhaust groove and the maintenance and cleaning during the production process, for the mold of glass fiber reinforced modified nylon products with complex geometry, is an effective method to solve the defects such as insufficient filling, compressed air burns, internal stress of the product, surface streamline and fusion line. The location, size, structure, addition of suction channels and special exhaust steel of the exhaust tank use, etc.; These are all ways of studying and widely used in good faith.

Nylon is a strong hygroscopic material, and only after sufficient moisture absorption can the parts achieve the corresponding physical properties; Its size will be relatively stable. For this characteristic that size increases with increasing water absorption, we achieve this balance through active humidity control and inventory time management. For critical dimensions, the mold size is corrected by means of dimensional data from the moisture absorption balance point.

We can provide a full range of solutions. The company has genuine Moldflow molding simulation analysis software; The product and mold design adopts software for mold flow analysis, considering the filling analysis, welding line, trapping, shrinkage marks, and glue feeding methods in advance, including the setting suggestions of injection molding parameters, providing professional analysis for the design and manufacture of products and molds and subsequent injection molding processes. Standard injection molding process; Regular maintenance of mold production process; Mass production quality analysis meeting; Ensure stable quality and continuous improvement of products.

Unternehmensvorteile

Frequently Asked Questions about plastic molding companies

QUICK LINKS

حالات مولان & الخدمات

CONTACT US