Компания по пластиковой формовании с службой настройки для многих отраслей - Mulan Group ![]()

Contact@china-plasticparts.com

+86 021 3479 1660

Contact@china-plasticparts.com

+86 021 3479 1660

Introduction to Plastic Injection Molding Process | MULAN

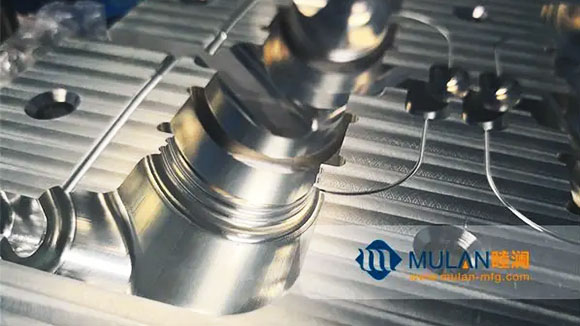

If you're looking to understand the ins and outs of plastic injection molding, then this article is the perfect resource for you. This comprehensive guide delves into every aspect of plastic injection molding , from the basics of mold design to troubleshooting common issues that may arise during production. With detailed explanations and insightful tips, this book will equip you with a solid understanding of how plastic injection molding works and how it can benefit your manufacturing processes. Whether you're a seasoned professional or just starting out in the industry, it is a must-have resource for anyone looking to master this essential manufacturing technique.

Extrusion molding, injection molding and blow molding are the main methods for the production of plastic products. This article will introduce the process flow and advantages and disadvantages of plastic injection molding.

Process principle of plastic injection molding

The principle of injection molding is to add granular or powdered raw materials to the hopper of the injection machine, the raw materials are heated and melted in a flowing state, driven by the screw or piston of the injection machine, through the nozzle and the mold pouring system into the mold cavity, hardening and shaping in the mold cavity. Factors that affect the quality of injection molding: injection pressure, injection time, and injection temperature.

Advantages of plastic injection molding

Plastic injection molding offers numerous advantages for businesses looking to manufacture products efficiently and cost-effectively. One major benefit of plastic injection molding is its ability to produce complex and intricate shapes with high precision, allowing for intricate designs that may not be possible using other manufacturing methods. Additionally, plastic injection molding allows for the production of large quantities of parts in a relatively short amount of time, making it ideal for mass production. Another advantage is the flexibility in material selection, as various types of plastics can be used depending on the desired properties of the final product. This versatility enables businesses to tailor their products to meet specific requirements while maintaining consistency and quality throughout production runs. Overall, plastic injection molding provides a reliable and efficient solution for companies seeking fast turnaround times, cost savings, and high-quality output in their manufacturing processes. In short, it has the main advantages as belowing:

1. Short molding cycle, high production efficiency, easy to achieve automation.

2. Can form complex shape, accurate size, with metal or non-metal inserts of plastic parts.

3. Product quality is stable.

4. Wide range of adaptation.

Shortcomings of injection molding

1. The price of injection molding equipment is higher.

2. Injection mold structure is complex.

3. High production cost, long production cycle, not suitable for single small batch plastic parts production.

Application range of plastic injection molding

The range of application of injection molding is very wide. For example, common kitchen supplies, garbage cans, bowls, buckets, POTS, tableware, electrical equipment shells, hair dryers, vacuum cleaners, food stirrers, toy bikes, car parts, tables, cosmetics packaging boxes, and other industrial products are injection molding products.

Plastic injection molding is a versatile and efficient manufacturing process that finds applications in various industries. From automotive to medical devices, consumer goods to electronics, plastic injection molding plays a crucial role in producing high-quality and cost-effective parts and products. Its ability to create complex shapes with tight tolerances makes it an ideal choice for mass production of components such as gears, housings, handles, and many more. The process involves injecting molten plastic into a mold cavity under high pressure, allowing for rapid cooling and solidification of the material. This results in consistent part quality and repeatability, making it a preferred method for businesses looking to streamline their production processes. With advancements in technology, plastic injection molding continues to revolutionize the way products are manufactured across industries worldwide.

About MULAN

QUICK LINKS

Случаи Мулана & Услуги

CONTACT US