Kunststoffformfirma mit Anpassungsdienst für viele Branchen - Mulan Group ![]()

Contact@china-plasticparts.com

+86 021 3479 1660

Contact@china-plasticparts.com

+86 021 3479 1660

What are the common thermosetting plastics?? | MULAN

Common thermosetting plastics include phenolic resin, urea-formaldehyde resin, melamine resin, unsaturated polyester resin, epoxy resin, silicone resin, polyurethane and so on.

Phenolic resin (PF)

Phenolic resin is one of the longest plastic varieties in history, also known as bakelite, the appearance of tan or black, is a typical representative of thermosetting plastics. Phenolic resin is mainly used in areas where heat resistance is required, and can also be used as a bonding agent for plywood, grinding wheels and brake pads.

Urea formaldehyde resin (UF)

Urea-formaldehyde resin is a colorless plastic made from urea and formaldehyde. Can be used as molding material, adhesive. The hardness and mechanical strength of urea-formaldehyde resin are excellent. But there are problems with brittleness and water absorption. Urea-formaldehyde resin can be used to manufacture tableware, bottle caps and other daily necessities and mechanical parts, and can also be used as adhesives.

Melamine-formaldehyde Resin (MF)

This plastic makes up for the water intolerances of urea-formaldehyde resins, but is more expensive. Melamine formaldehyde resin and urea formaldehyde resin as colorless transparent, forming color, heat resistance, surface hardness, mechanical properties, electrical properties, water resistance, solvent resistance and chemical resistance is superior, so it can be used in tableware, daily use, furniture, industrial supplies and so on.

Unsaturated Polyester Resin (UF)

Unsaturated polyester resins are transparent liquids of light yellow or amber color with different viscosities. It is usually used with reinforced materials such as glass fiber, called glass steel. Unsaturated polyester resin can be molded without pressure and can be cured at room temperature, so it can be processed into products by various methods.

Epoxy Resin (EP)

Epoxy resins are thermosetting plastics cured with curing agents. It has excellent adhesion, excellent electrical properties and good mechanical properties. Its main use is as metal anti-corrosion coatings and adhesives, often used in printed circuit boards and electronic components of the seal casting.

Silicone Resin (SI)

Silicone resin has excellent heat resistance and cold resistance, and can even withstand 500 ° C after special treatment. It is a thermosetting plastic with excellent chemical resistance, water resistance and weather resistance, and is often used in the production of electronic industry components.

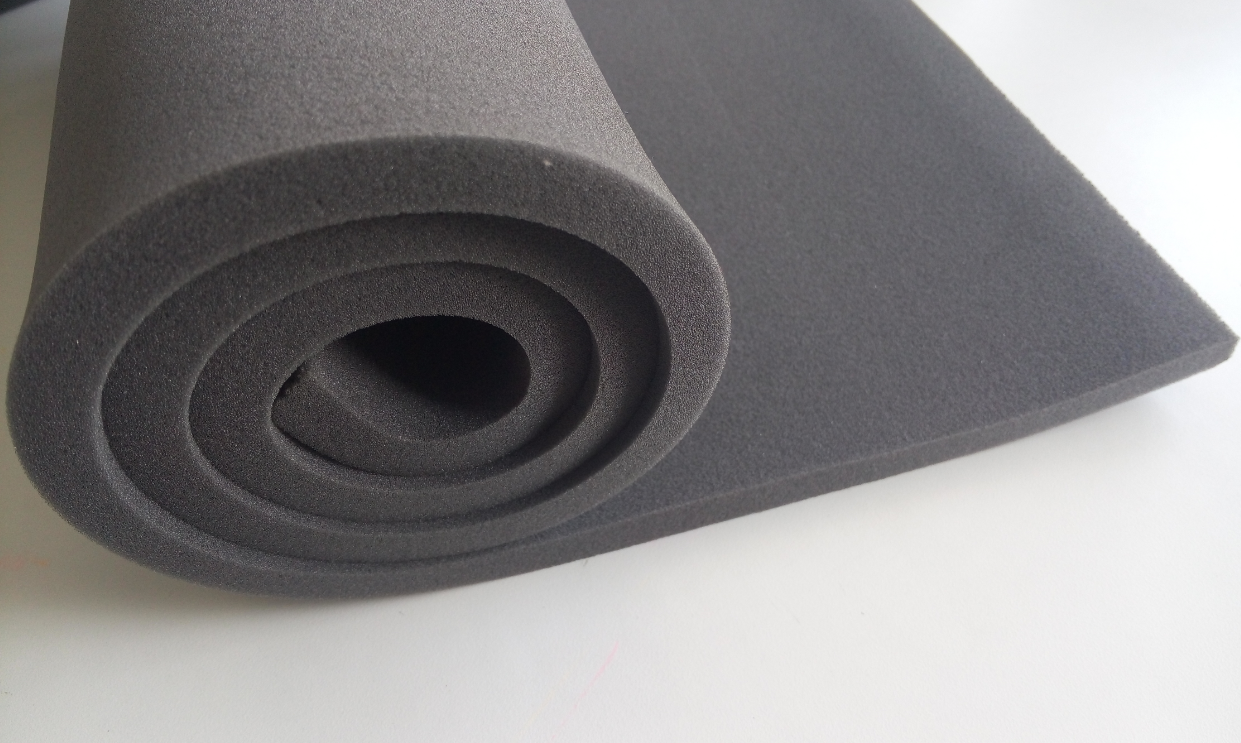

Polyurethane

Polyurethanes come in many varieties and are mainly used to make foam. The density of soft foam is 0.015 ~ 0.15g/cm3, mainly used for furniture and packaging materials.

About MULAN

QUICK LINKS

Mulan Fälle & Dienstleistungen

CONTACT US