Plastic Molding Company with Customization Service For Many Industries - Mulan Group ![]() Contact@china-plasticparts.com +86 021 3479 1660

Contact@china-plasticparts.com +86 021 3479 1660

amazing best injection molding parts company | MULAN

At MULAN, technology improvement and innovation are our core advantages. Since established, we have been focusing on developing new products, improving product quality, and serving customers. best injection molding parts We have been investing a lot in the product R&D, which turns out to be effective that we have developed best injection molding parts. Relying on our innovative and hard-working staff, we guarantee that we offer customers the best products, the most favorable prices, and the most comprehensive services as well. Welcome to contact us if you have any questions.This product brings economic benefits to customers with bright industry prospects.

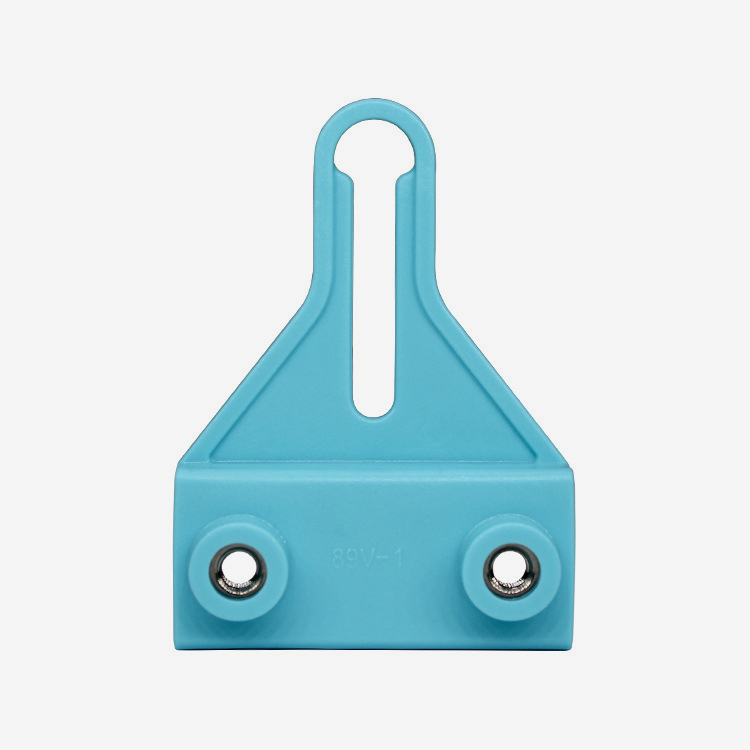

Products name | Custom plastic Injection mold |

Color | clear (standard clear or high optical clear), semi-transparent, other colors (pantone code #, or made to client’s sample) |

Size | All size and thickness available.According to your drawing |

Material | PP, ABS, PC, ABS+PC, Nylon, Delrin (POM), PMMA, AS, PS, PE, PET, PVC, PEEK, etc; GF added material (ABS+GF, PA66+GF, PA666+GF); Rubber (TPE, PU, NBR, silicone, NBR+TPE etc) |

Injection mold style | Edge gate, side gate, sub gate, direct gate, pin point gate, valve gate |

Mold material | NAK80, S136, SKD61,45, S55C, P20, 1730, 2738, 718h, H13, BPMHH, 2343ESR |

Mould life | 300,000 - 1,000,000 shots |

Injection molding process | Plastic over-molding molddouble color injection moldinsert moldingMulti-cavity moldsingle cavity moldFamily mold toolingHot runner mold toolingTooling assembly and product assemblySecondary OperationsRapid prototyping tooling |

Cavity | Single or multi: 1*1, 1+1, 1*2, 1+1+1, etc. |

Runner | Hot or cold |

Design software | Soliderworks/UG/engineer(3D)Autocad(2D)Moldflow analysisMastercamDFM |

Equipment list | High speed CNC, standard CNC, EDM, Wire Cutting, Grinder, Plastic Injection Molding Machine for testing mold from 50-3000T available. |

Product tolerance | Min 0.01mm |

Mold production | turning, grinding, milling, screw holes, water carrying hole, center hole, CNC roughing, etc. |

Minimum quantity | 1-1000000parts,unlimited Minimum quantity |

Standard | ISO 9001-2015、TS16949、RoSH and SGS standard |

Mold core material | P20, 738, 738H, 718, 718H, NAK80, 2316, 2316A, S136 etc. |

Product weight | 5G-30kg |

Mold building lead time | 15-40 days depends on qty & complexcity mold |

Product quality control | 5%-10% sampling |

Shipping transportation | Fob/exwork |

Product application | scracth resistant, flame resistant, UV resistant, food grade, chemical resistant, etc.Automotive industry, electronic and electrical appliances, medical industry, fiber-optical and transmission industry and customized components, concerning connector molding parts, auto parts, medical parts and other tooling, etc. |

After-sale service | Permanent free after-sale. |

Surface treatment | texture (VDI/MT standard, or made to client’s sample), polished (high polish, mirror polish), smooth, painting, powder coating etc. |

QUICK LINKS

mulan Cases & Services

CONTACT US