Plastic Molding Company with Customization Service For Many Industries - Mulan Group ![]() Contact@china-plasticparts.com +86 021 3479 1660

Contact@china-plasticparts.com +86 021 3479 1660

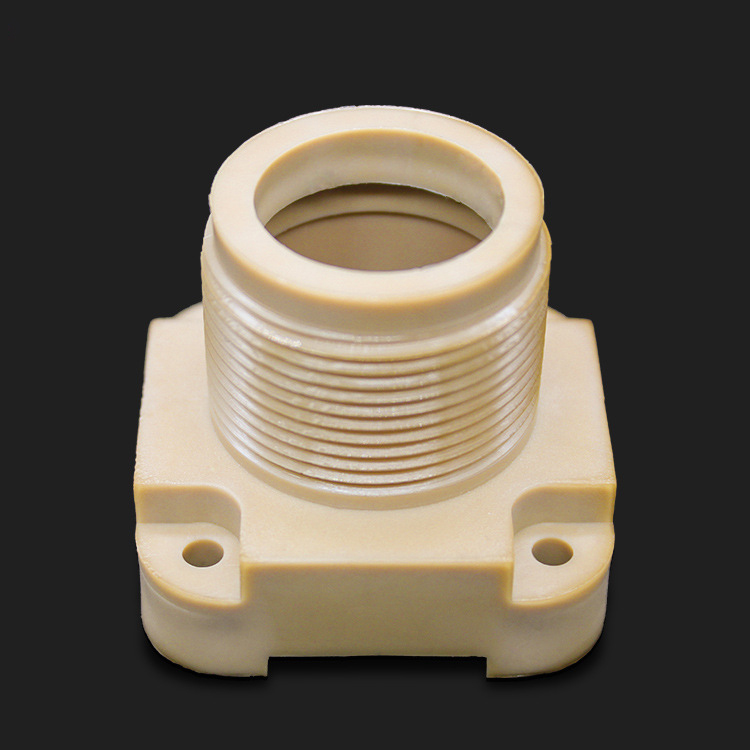

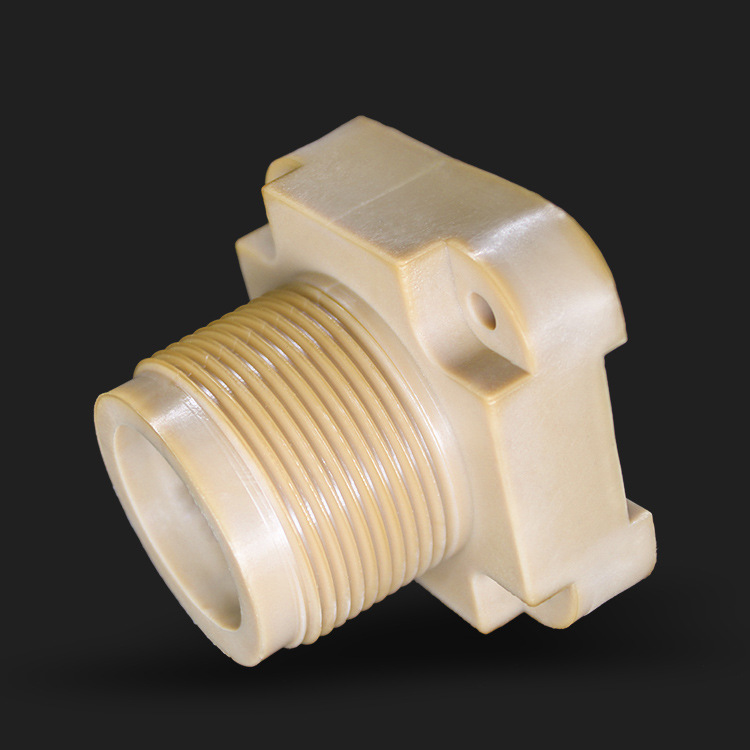

Customized PEEK support base manufacturers From China | MULAN

PEEK support base compared with similar products on the market, it has incomparable outstanding advantages in terms of performance, quality, appearance, etc., and enjoys a good reputation in the market.MULAN summarizes the defects of past products, and continuously improves them. The specifications of PEEK support base can be customized according to your needs.

Precision PEEK plastics parts, high temperature resistance, no corrosion, can meet with different working condition requirements, and so to meet the production demands. Welcome to send us the RFQ for custom productions.

About MULAN

Product Introduction

Product Information

Company Advantages

Frequently Asked Questions about plastic molding factories

China Mulan Manufacture Group is an ISO 9001-2015 OEM plastic molding parts manufacturer, specializing in the production of plastic injection molding, rotational molding, blow molding and other customized plastic molding parts. We actively provide one-stop technical support and manufacturing services for custom plastic parts buyers in various industries around the world.

We have a professional injection molding technical team, with more than 8 engineers specializing in injection mold design, to provide one-stop service from product design, mold tools, technical support, consulting services, sample manufacturing, mass production, packaging and shipping.

We have rich manufacturing experience, and from North America, the United States, Canada, Germany, France, Italy, Spain, the Netherlands and other countries in a variety of industry manufacturers, wholesalers, trading companies and agents long-term cooperation, we are confident to become your most reliable OEM custom plastic molding parts supplier.

QUICK LINKS

mulan Cases & Services

CONTACT US